Latest Work: Skull Bike Polo Head Badges

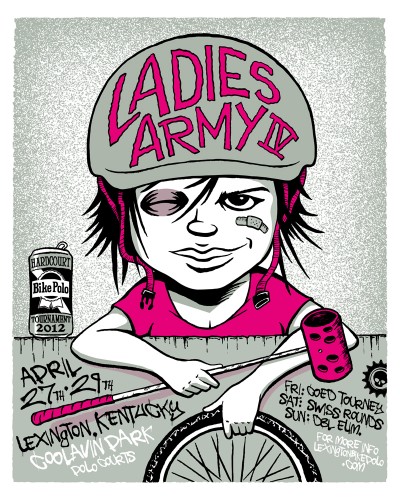

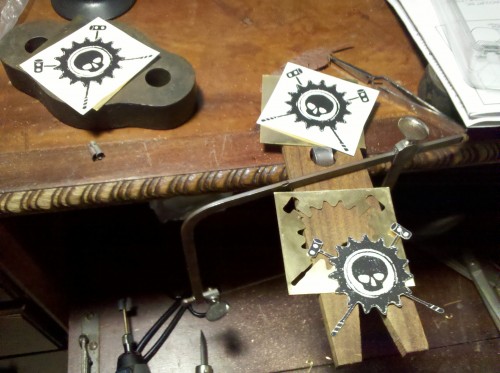

Written by Boston Biker on Mar 26I am making these to donate them to an all ladies bike polo tournament, and I have to admit I am really loving the way they are coming out. Its the first time I have made three “identical” head badges, so I thought I would take some process photos to show you how these are made.

My process is usually one of designing the badge on the computer and then printing it out and rubber cementing it onto the metal for the cutting.

After that you have to clean up all the pieces, to make sure they are nice and smooth for soldering.

Then you have to sweat solder all the pieces together, this involves a two step process of putting solder on the backs of the top pieces (the copper cog and skull), lots of flux and torching later you have two pieces with a nice layer of solder on the back, then you clean them up, flux em again, flip em over, onto the brass back piece, and heat the brass piece until the soldier runs out to the edges of the copper pieces.

Then its into the pickle Once out of the pickle you clean it up again with ever finer grain sand paper, until its shiny and good, then into the tumbler for a couple hours to get that super high shine, a quick bend over a pipe, and a quick dip in protective coating, and tada head badge!

You can see my other work here, and even buy them here.

Tags: brass, copper, head badge, skull

Posted in crafts | 2 Comments »

Sorry, comments for this entry are closed at this time.